Supply Chain Problems: How Drug Shortages and Manufacturing Issues Affect Your Medications

When you need a medication, you expect it to be there—simple as that. But supply chain problems, breakdowns in the system that moves drugs from factories to pharmacies. Also known as pharmaceutical distribution failures, these issues are now a daily reality for millions of patients. It’s not just about delays. It’s about your blood pressure pill, your insulin, your asthma inhaler—gone or hard to find. This isn’t a one-time glitch. It’s a growing pattern tied to how medicines are made, shipped, and regulated worldwide.

Behind every pill is a long, fragile chain: raw ingredients from overseas labs, chemical synthesis in factories with strict quality rules, packaging in clean rooms, then shipping through global ports that get clogged or delayed. A single factory in India or China with a quality violation can shut down supply for an entire class of drugs. pharmaceutical manufacturing, the process of producing medicines under strict regulatory standards has become more complex and less resilient. When a plant fails an FDA inspection, it doesn’t just pause production—it can take months to restart. And when that plant makes the only version of a drug you need? You’re stuck.

These problems don’t stay in factories. They hit your pharmacy shelf. medication shortages, when a drug isn’t available in sufficient quantity to meet patient demand have jumped over 300% in the last decade. You might get a different brand, a lower dose, or worse—nothing at all. Even if your doctor prescribes the right thing, the system fails you. And it’s not just about big-name drugs. Even common generics like metformin or levothyroxine have vanished from shelves. These aren’t rare edge cases. They’re the new normal.

And it’s not just factories. drug distribution, how medicines move from wholesalers to hospitals and pharmacies is full of bottlenecks. Truckers are short. Warehouses are full. Customs checks take weeks. A shipment of active ingredients stuck in a port can mean thousands of prescriptions go unfilled. Meanwhile, the cost of making drugs keeps rising, and some companies stop making low-profit generics altogether. That’s not business—it’s a public health risk.

You don’t need to understand global logistics to know when your medicine isn’t there. But understanding why helps you act. If your prescription is suddenly unavailable, it’s not your fault. It’s not your doctor’s fault. It’s a system under strain. And that system affects everything from your blood sugar to your heart rhythm. The posts below show how these problems show up in real life: from barcode scanning failures in pharmacies to quality control breakdowns in manufacturing, from drug interactions caused by last-minute substitutions to how patients are forced to switch treatments mid-course. These aren’t theoretical concerns. They’re daily struggles for people managing chronic conditions.

What you’ll find here aren’t just stories about shortages. They’re practical guides on how to spot the signs, protect yourself, and work with your provider when the system lets you down. You’ll learn how to track your meds, ask the right questions, and avoid dangerous swaps. Because when the supply chain breaks, you’re the last line of defense.

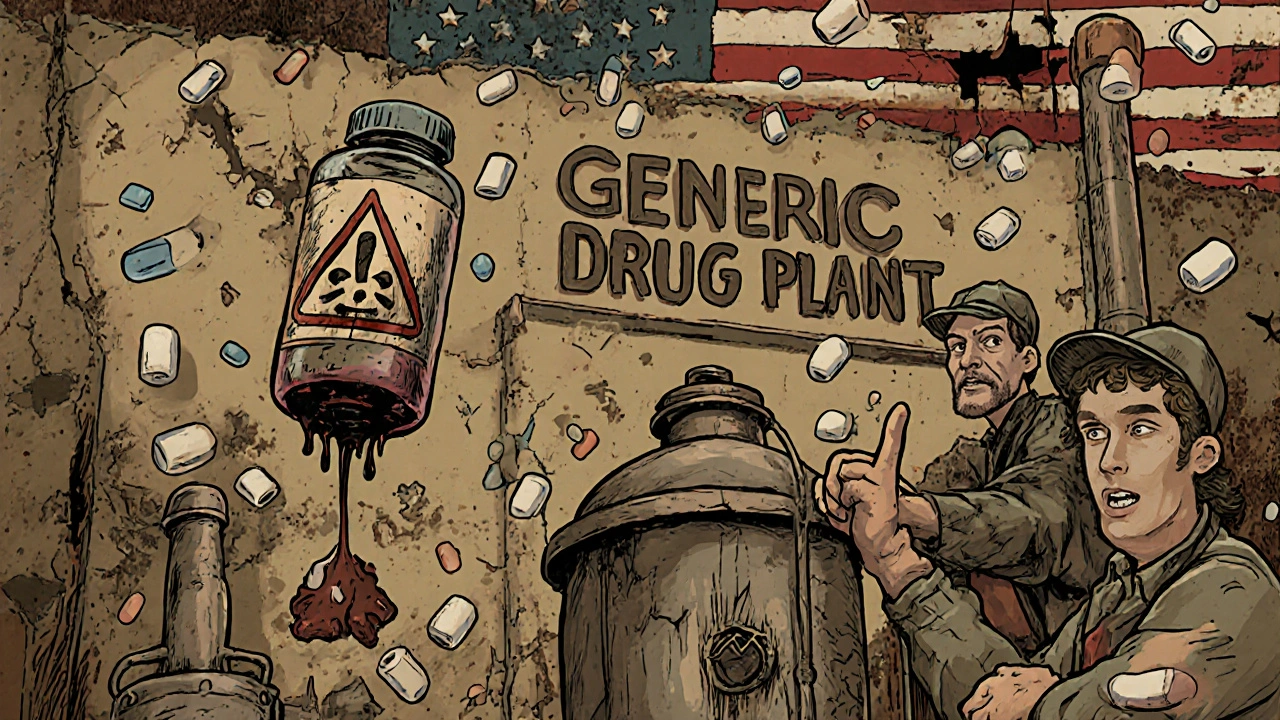

Causes of Generic Drug Shortages: Manufacturing and Supply Chain Issues

Generic drug shortages are caused by fragile manufacturing systems, global supply chain risks, and broken economics. Over 60% of shortages stem from production failures, with most active ingredients coming from just two countries. Low profits discourage investment, leaving no safety net when things go wrong.